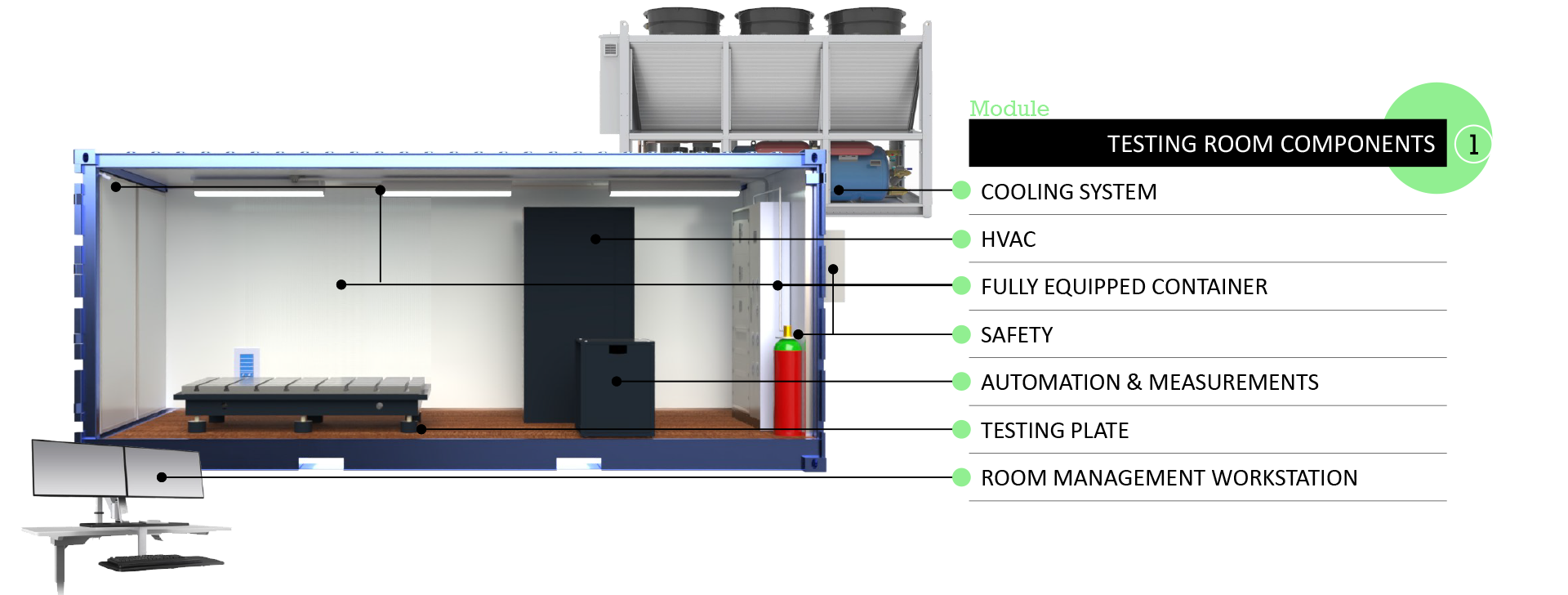

TESTING ROOM Components

EVSYS is an EV Testing Room, a flexible, cost-effective, and mobile test facility built inside a containerized structure. It’s an ideal solution for developing and testing e-powertrains and related components.

EV Testing Room is a “Self-Integrated-Safety” room inside a fully equipped container

Soundproofing Panels

All the internal walls and doors are equipped with panels with these features:

– Thickness: 50mm

– Insulation: -31 dB

– Absorption: AW=0.90

– Certification: CAM, BREEAM

– Fire reaction class: A2-s1,d0

– EI30

Testing Plate

Main features:

– Made of EN-GJL-250

– Surface machined to DIN 876/III

– Transversal and longitudinal T-slots to DIN 650-28H12

– 6 regulating elements vibration-cushioned type RSe30-200

– including oil channel made of U-profile

Fire Detection, Extinguishing & Safety Management

– Temperature notifier

– Smoke notifier

– Extinguishing system

– Fire control unit

– Safety PLC

– Safety management interface on automation HMI

Remote monitoring

– Camera Control

– Internal lighting

Chillers & Cooling plant

CustoM 2.0 provides n. 1 chiller for the cooling of the bench equipment and n. 1 regulated chiller for the DUT

HVAC

The HVAC (Heating, Ventilation, and Air Conditioning) is a system used to regulate indoor temperature.

To obtain reliable and significant results from the tests carried out inside the test room, CustoM 2.0 integrates the HVAC system to maintain a fixed temperature of 25°C during testing cycles.

Automation and Control

The Automation and Control is based on National Instruments® NI-PXIe® with its communication and control boards and the Control Fanless PC.

The software NI VeriStand® is able to process, as an input of the testing room, the virtual models coming from Mathworks®. The automation of the testing and measurements allows an easier use by the operator and the reporting of the tests.

Measurements – Power Analyzer

The Measurements are done with the HBK® Genesis GEN4tB® system with its acquisition modules and sensors.

The HBK solution composed by the Hardware Genesis and the Software Perception together with the current sensors and the torquemeter has a native synchronization of the measurements of the electric power with the mechanical power.